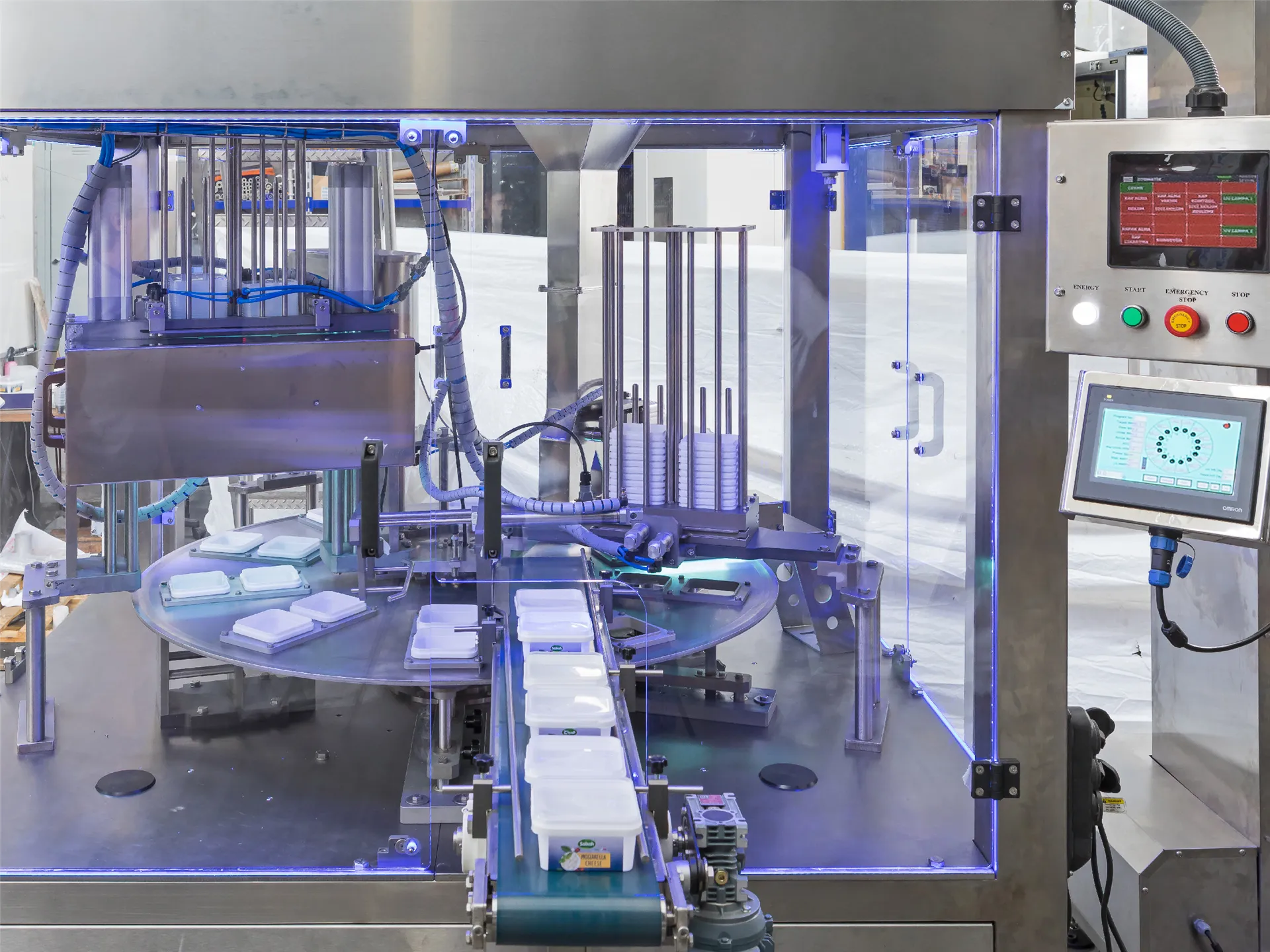

Rotary Tray Sealer Machine - AT-TR (TRAY ROTARY)

Rotary Tray Sealer Machine - AT-TR (TRAY ROTARY)

Our machine is mainly used for food products. Depending on the product, changes can be made to the production line. If required, it can automatically fill various food products such as ketchup, mayonnaise, honey, olives, nuggets, nuts, cheese, poultry, coffee, or soup. The ready-made cups placed in the magazine are picked up by the suction mechanism and positioned onto the pallet conveyor line, where they are transported to the filling station. At the filling station, the cups are filled with the desired accuracy (depending on the product’s viscosity). Afterwards, the machine automatically transfers the cup to the sealing and cutting unit, where the top foil is sealed and cut. Once this process is completed, the machine transfers the cup to the capping unit for lid placement and pressing. Finally, the cup is conveyed outside via the conveyor belt. If desired, printed foil can also be used. Since all components, including the main chassis and legs, are manufactured from 304-grade stainless steel and sheet profiles, the machine is highly durable even under the toughest working conditions. The mechanical components are made using the world’s highest quality materials